The concept of the circular economy and its focus on recycling and reuse have been gaining traction in the business world for years. Often synonymous with sustainability—an important focus in today’s market—circular economy models are now moving increasingly from theory to practice.

Top organizations have assigned teams to innovate and optimize, and for businesses, people and the environment, it’s go time.

However, according to recent research commissioned by the United States Postal Service, the term “circular economy” is unfamiliar to many logistics professionals and seems intangible to most businesses.[1]

“I'm not really worried about sustainability, I'm more worried about meeting my goals. It’s not forgotten about, but it's not a priority.”

— COO of a precious metals/collectibles company

The finding is somewhat surprising given the growing adoption of circular practices. Shippers unversed in the latest and most important trends risk losing ground to more agile competitors whose businesses are profiting from becoming circular.

Our research examined several key areas related to how companies are approaching and preparing their supply chains for circularity: What are the plans for their product’s end of life? What sustainable packaging trends are they investing in? How are they optimizing reverse logistics? What tech innovations can help?

Here, we look at the challenges and opportunities the shipping decision-makers we interviewed are seeing as they adopt a circular approach.

What Is the Circular Economy and Why Now

Take, make, waste—the traditional consumption model doesn’t care much about what happens next. Goods are simply used, often without thought of how they consume finite resources and contribute to the more than 100 million tons of waste that end up in landfills every year.[2]

This linear model tends to offer higher profits for companies, cheaper prices for consumers, and less effort overall. But at what cost? The waste and pollution are significant. And the materials management is nonexistent at a time when scarcities and inefficiencies are top of mind.

A circular economy, on the other hand, is built on reuse. The resources claimed to produce an item are strategically kept in use for as long as possible, then circulated back into production through a process of recovery and renewal.

The idea of the circular flow of materials has been discussed for decades, with great hope for its social, economic and environmental benefits. Today, consumers are paying closer attention, assessing sustainability with urgency.

The Role of Shipping in the Circular Economy

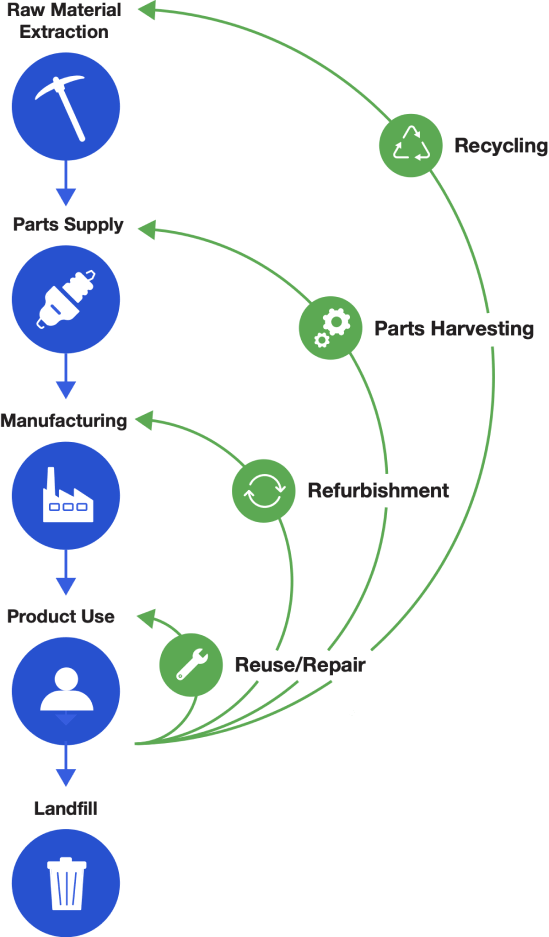

At this point, most people can agree on the principles of circular flow: Eliminate waste and pollution, keep materials and products in use, regenerate nature. It’s a system comprised of recovery, repair, refurbishment, reuse and recycling.

But the specifics of circular flow can be wide-ranging depending on the business, which may be a reason why shippers are feeling unsure and overwhelmed. Which changes should come first? What technology solutions can help with the process? Where will the cost and effort be most worthwhile?

One thing is certain—shipping plays a critical role in the shift to a circular economy.

The loops featured in every circular economy diagram? They represent the valuable movement of goods. Each requires shipping and logistics—and each is a business opportunity that will eventually be worth the effort.

The Challenges of Becoming a Circular Business

Moving from a linear to a circular economy requires companies and consumers to adjust their mindset and their behaviors, which presents challenges, particularly for small businesses.

The professionals interviewed pointed to a range of obstacles that make circular efforts complex, and progress slow moving.

High Costs

An end-to-end business transformation isn’t easy. It takes time, money and complex coordination. With other more pressing priorities in the wake of COVID-19’s disruption, the additional expense of implementing sustainable solutions is a concern for many businesses.

The cost of more returns plus the uncertainty of how sustainable efforts will impact the bottom line make it a risk many logistics teams are not willing to take right now.

“Prices of everything are increasing with the times that we're in from COVID; the gas rates are higher.… Now that the whole state of the world is kind of changing day to day, there's a lot of flux. That's been a challenge lately for sure.”

— CEO of a personal goods manufacturer

Environmental Trade-Off

The act of eliminating waste and recycling rather than harvesting seems ideal on the surface. But the logistics involved may cast some doubt. Some professionals point to the carbon emissions that end-of-life returns create and wonder if reusing is truly beneficial.

The hope is that increased collaboration, both among teams and with other innovative organizations worldwide, can help find efficiencies.

Quality of Sustainable Packaging

Some are investing in eco-friendly packaging materials, but results have been mixed. For example, recyclable tape and cardboard rather than Styrofoam have proven to be a successful alternative. Yet, some interviewees think innovative materials such as bamboo and mushroom often seem more gimmicky than useful.

Sustainable packing must satisfy needs for durability and its use become more widespread to be economically viable.

Complexity of Planning

Sustainability is more high level at many companies, with some overall green goals in place. For circularity to be implemented, a coordinated strategy that involves all aspects of product design, sales, marketing and supply chain is required, as well as communication with the end consumer.

In addition, logistics play a central role. As they are critical to the circular flow, logistics teams can spearhead implementation—working with engineers and executives to make strategic decisions and set goals that instigate the right progress across their business.

The Steps to Take Now

How can a business successfully participate in the circular economy? It doesn’t have to happen all at once. Start by assessing where your business stands on the path to sustainability and innovation, and find opportunities to streamline operations.

- Switch to eco-friendly packing materials

- Find software to consolidate box units

- Clearly communicate initiatives to consumers

- Set deadlines for adopting circular design principles

One example of a simple innovation that some businesses have successfully implemented is saving and reusing inbound boxes—a relatively easy step that provides cost savings.

“We reuse packages and have a little stamp that we put on those boxes that indicates we are giving that box a second, third, sometimes fourth life.”

— President of a boardsports retailer

Additional strategies to consider:

Form Creative Partnerships

Cooperation between teams and industries has the power to make circularity more attainable. An essential partnership to start with is with design teams. For the circular system to work, products must be designed to be repaired, refurbished, recaptured and reused.

Logistics teams have key knowledge here and can collaborate with research and development to maximize materials. Which raw materials are more innovative? Which can be reclaimed and reused most effectively? Where should the focus be to help stave off competition for supplies?

Also, connect with the sales department. Where are the greatest opportunities? Are there innovative ways to use refurbished products? What will help ensure a pipeline of products to recycle? Tech companies are often savvy in this area, with promotions that enable them to reclaim and resell inventory.

“It's a collaboration between marketing and sales and engineering.”

— CFO and co-owner of an independent audio equipment manufacturer

Optimize Reverse Logistics

With today’s heavy volume of e-commerce returns, the common sentiment among businesses is that reverse logistics can be a costly struggle. Committing to improving with circularity in mind may benefit.

Make the return process as simple as possible. Again, this can involve the design phase—creating packaging that’s reusable for returns is one place to start. And making products easy to disassemble for shipping is another.

Access is also important, for consumers and for companies. Customers want easy pickup or drop-off. Companies will want to figure out individual collection versus the mass output of forward logistics, and this is where a carrier can help streamline.

Explore the Second Loop

Carriers can also play a critical role in helping businesses develop new revenue streams from second- and third-life products. Items that can be easily rented or resold—such as clothing and electronics—lend themselves to circular flow.

The resale market is growing 11 times faster than traditional retail.[7]

If a business sees an opportunity to expand in this area, they’ll need to not only assess design to be sure their products are set up for a circular lifestyle, but they’ll also need to ensure a process of getting items back from users efficiently.

Adopt New Technology

Seek out the right technology solutions. From product traceability to finding the smartest use of recycled components, circularity can be made easier and more profitable through advanced technology.

“Before COVID I would've said more people, more knowledge, more hands on. After COVID, I'm leaning more towards smarter, not harder, and how can we automate it?”

— Global distribution manager at a technology company

For instance, an equipment manufacturer can fit its products with sensors that collect data on their condition, which enables it to quickly identify whether a returned product’s components can be reconditioned. Or a logistics team can use a more advanced automated returns process online rather than a manual process.

Educate and Engage Customers

More consultative customer service can help set expectations, pre-empt issues and drive engagement. Helping to purchase the right product and troubleshoot issues, for example, can prevent unnecessary and costly returns.

Regular communication will also guide consumers in the process of maintenance, repair, returning and recycling to ensure circular efforts are successful.

Key Takeaway

The idea of a circular economy is not new. But with consumers becoming increasingly interested in sustainability, and economic and environmental pressures growing, businesses now are actively moving from concept to action.

The keys to success for a company: Connecting the unconnected in new, innovative and, ultimately, profitable ways. Collaborating across disciplines. Forming partnerships to achieve scale. Closing loops to enable efficient recovery and reuse.

It’s time to overcome uncertainty and ready your organization. Because today’s circular efforts are not only reducing environmental harm but maximizing business opportunities.

search

close

menu

search

close

menu